Modding the Thermaltake Bigwater 760i Water Cooler

Posted: Tue May 13, 2008 12:38 pm

Curious as I am I decided to dig deeper into the 760i and see if there was something I could do to up the performance for cheep.

First thing I thought of was the QD fittings, yeah they make life nice getting the system in and out; but it could be restricting flow and who takes the system apart on a regular basis other than someone who does reviews. Well I removed them and was surprised that they were 1/4” fittings.

Too look at the tube from the side you would think that it was a thin wall 3/8” ID neoprene tube.

Nope 1/4”, well that can’t be helping things any.

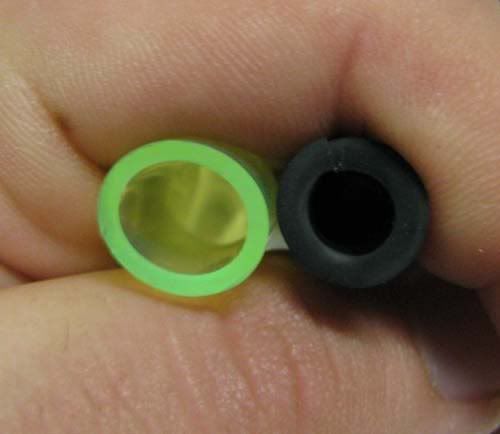

Enter Danger Den 3/8” high flow stubby’s, since the P500 pump has G1/4” ports you have more options than you can shake a stick at. Here is the stubby fitting next to the stock hose barb.

You can see they have a little more throat than the stock fittings. Yes I know its a stubby's are a larger fitting, but you get the point. Actually you can put the stock barb inside the DD fittings. This should help a bit and I'm only out $5+shipping.

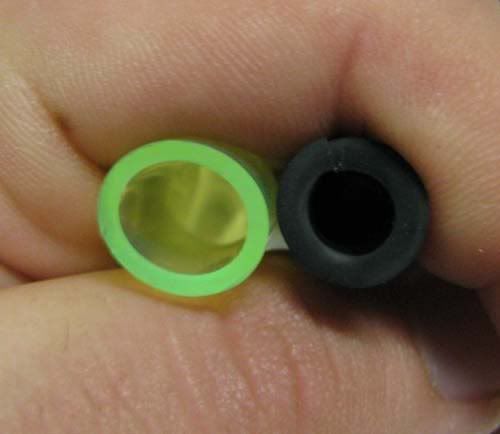

Well I got to thinking of the fittings on the water block. Well the fittings are not G1/4 fittings, not sure what they are, but they are small to say the least. So everything I did above may not help a bit, but I’m learning something in trying. Above is the stock fitting (lower) next to a Koolance 3/8" high flow connector.

With everything slapped back together I leak tested it and stuck it back on the test system to see if I gained anything form the changes or if my $5 worth of fittings was a waste, and it wasn't.

With the Q6600 oc'd to 3.0gHz the idle temp dropped by a degree and the load temp dropped 2.5*C, with a before core temps of 44/40/43/43 to the after of 43/37/40/40.

I think is was money well spent. now, what to do about the block.

First thing I thought of was the QD fittings, yeah they make life nice getting the system in and out; but it could be restricting flow and who takes the system apart on a regular basis other than someone who does reviews. Well I removed them and was surprised that they were 1/4” fittings.

Too look at the tube from the side you would think that it was a thin wall 3/8” ID neoprene tube.

Nope 1/4”, well that can’t be helping things any.

Enter Danger Den 3/8” high flow stubby’s, since the P500 pump has G1/4” ports you have more options than you can shake a stick at. Here is the stubby fitting next to the stock hose barb.

You can see they have a little more throat than the stock fittings. Yes I know its a stubby's are a larger fitting, but you get the point. Actually you can put the stock barb inside the DD fittings. This should help a bit and I'm only out $5+shipping.

Well I got to thinking of the fittings on the water block. Well the fittings are not G1/4 fittings, not sure what they are, but they are small to say the least. So everything I did above may not help a bit, but I’m learning something in trying. Above is the stock fitting (lower) next to a Koolance 3/8" high flow connector.

With everything slapped back together I leak tested it and stuck it back on the test system to see if I gained anything form the changes or if my $5 worth of fittings was a waste, and it wasn't.

With the Q6600 oc'd to 3.0gHz the idle temp dropped by a degree and the load temp dropped 2.5*C, with a before core temps of 44/40/43/43 to the after of 43/37/40/40.

I think is was money well spent. now, what to do about the block.